Limoges, France is located 229 miles southwest of Paris. The city of Limoges has a population of 200,000 and is the 22nd largest city in France.

In the 18th century, major deposits of high quality kaolin clay were discovered. Consequently, the region grew quickly famous for its production of fine artistic porcelain china and boxes.

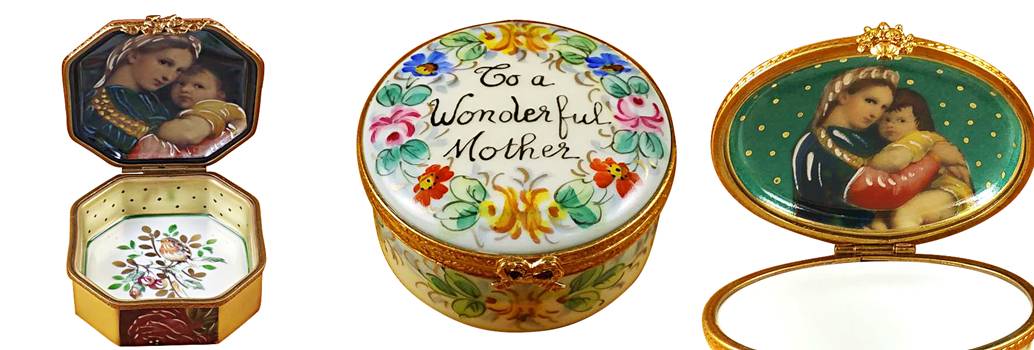

Limoges boxes have a diverse history. Over the centuries, products have ranged from large candy and jewelry boxes to smaller boxes suitable for the storage of pills, rouge, powders, snuff and small personal items.

Limoges boxes vary in the quality and detail of the design, the amount of labor and artistic skill involved in casting, firing and decorating, and the number of pieces produced. Naturally, the price of a box varies accordingly. Each piece is marked by hand, in French; to indicate that it is an original, hand painted creation. The finished box with the world famous insignia, Peint main, “hand painted” can be found on any authentic box. These beautiful Limoges boxes make wonderful gifts and decorative accessories.

The Limoges box process begins with sketches, drawings and/or watercolors. A sculptor takes these and creates a model from plaster and/or clay for the original mold. Depending on the complexity of the form, the mold could consist of three separate parts to as many as 30 or 40 pieces. These pieces fit together like a puzzle, the negative cavity inside creating the positive shape in porcelain. Once the prototype is approved for form, a “mother” mold is created from silicone or resin, from which many production molds are made. The production molds wear out after 50 to 80 uses; thus new production molds must constantly be made from the mother molds.

Each piece is then hand poured into the mold. The thick liquid is created from a mixture of quartz, feldspath, and kaolin. It is left to stand a few seconds to thicken the wall of the piece, and then the remainder is poured out. Afterwards, it is removed from the mold very carefully by hand and left to dry for a day or so. Each piece is then hand finished, meaning edges caused by the joints in the mold are removed. Then the piece is fired at approximately 900 degrees Celsius to dry it out completely and make it ready to accept (absorb) the enamel. Each piece is then hand dipped into a bath of enamel (the same mixture of quartz, feldspath and kaolin, but in different proportions). This enamel is actually clear. The beautiful white result shining through is the color of this porcelain and the reason why it is so famous. Then the pieces pass into the “grands feux” or hottest kiln, and are fired at 1400 degrees Celsius (a 24-hour process, 12 to fire and another 12 just to cool down the kiln enough to be able to open it).

Now the pieces pass into the hand painting studios. The spectrums of colors are fired at different temperatures, for example, blues and purples are fired from 750 – 900 degrees Celsius, whereas reds are fired at between 550 and 700 degrees Celsius. Reds will in fact disappear (be burned away) at higher temperatures. Therefore, depending on the number of colors, a piece could go through the kiln as many as 5 or 6 more times. Each piece is signed, and sometimes numbered by the artist with the ever important identifying “peint main”, meaning “hand painted”, and Limoges, France, written on the bottom, certifying that you have indeed purchased a truly unique, completely handcrafted piece.

Porcelain undergoes shrinkage of 13-15% during the major firing of 1400 degrees, with differences in vertical versus horizontal shrinking. Therefore, although the pieces are poured from the same mold, each one has slight variations and is unique. This fact means that standardized hinges are an impossibility. Each piece is individually fitted by hand with a brass hinge and each clasp (usually a whimsical creation, highly detailed, recalling the ‘story’ of the piece) is soldered on by hand. Any additional metal, leather, glass and other material add-ons are applied by hand at this point.